Five steps to build a culture of continuous change and realize sustainable productivity results.

Axsium’s industrial engineers and workforce management specialists have spent decades identifying and implementing process improvements for our customers.

Regardless of whether process improvement is the primary focus of a project or a value-added opportunity that we uncover along the way, the Axsium team is always on the lookout for improvement opportunities. In fact, we encourage our clients to adopt the same mindset.

We have translated these insights and experiences into five straightforward steps to help your organization get started:

- Step 1: Get to know the proven methods.

- Step 2: Get acquainted with the tools.

- Step 3: Get your ideas prioritized.

- Step 4: Get testing in the field.

- Step 5: Get ready to adopt.

In our last blog, we outlined how to organize, quantify, and prioritize your process improvement backlog. Now your highest priority ideas are nearly ready to implement. But first you need to test them in the field.

Step 4: Get Testing in the Field

Let’s jump right into the tablets example we’ve been using. In our example, the client was considering using tablets to improve the process of managing inventory. Clearly, they wouldn’t be able to implement this kind of change overnight.

There’s a simple pattern to implementing your ideas so you get the best out of them. First, you need to test different apps or varieties of configurations to prove out the most efficient, cost-effective, and field-approved process. Then—and only then—do you ramp up to the pilot.

But isn’t testing the same as piloting? Not exactly. Testing offers an opportunity to iterate and learn about the proposed process change in a real-life setting. Piloting, on the other hand, provides a static trial of the presumed final process before going live.

In essence, what you’re trying to achieve with the two things is different. A test aims to work out the kinks and ensure that success can be measured. Meanwhile, a pilot aims to evaluate the results and finetune your change management strategy. We’ll talk more about piloting and implementing your ideas in the next and final blog of our series. In the meantime, let’s roll up our sleeves and get busy testing.

Which Ideas Need to be Tested?

So, do you test all your options at once? Or one at a time? We don’t have an easy answer to that question, so let’s ask a couple of simpler questions. What’s easiest? What has the potential for the biggest return?

Why choose “what is easiest?” It’s simple, really. The easiest idea to test will bring early success, which is a great morale boost for your project team. Quick wins sustain and feed momentum. This will be critical in helping you to sustain your team’s continued efforts.

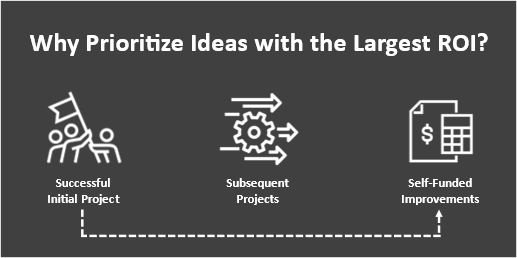

And why choose “what has the potential for the biggest return?” Another simple answer! The idea that leads to the biggest return will, if successful, help the continued effort pay for itself and more. It’s always a plus to be playing on house money. But unlike gambling, the house money will continue to be brought in—there’s no risk here.

We all know how exhausting it can be to constantly address the question “how is the project progressing?”. One way to reduce the need to update upper management is to quickly and effectively prove out ROI early in the testing cycle.

Toward that end, process improvement ideas with measurable hard savings tend to be the easiest to prove out success. Soft savings can be more difficult to quantify, but they can also be useful as their benefits often have the greatest impact on team morale.

The Composting Solution

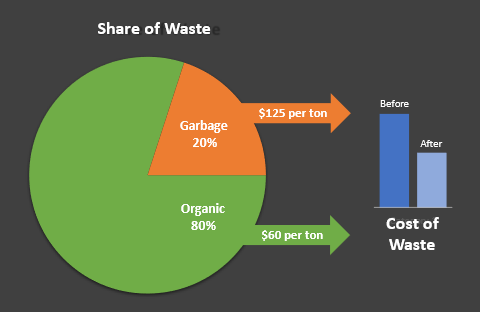

Years ago, a grocer in the western United States assembled a team to research the cost of their waste. The team found that 80% of the waste they generated was organic. Their garbage was costing them $125 a ton, while their organic waste was only costing them $60.

The team discovered local composters were looking for food waste in addition to their regular grass trimmings and leaves. This was because food waste increases the porosity of the matter they compost.

The team decided to test the proof of concept (POC) for diverting organic waste from the garbage stream at a single store. Fortunately, one of their store managers was on the team and volunteered as the test store.

The grocer made green composting bags available for each department. They also provided training for store associates to identify acceptable composting waste. And the local composting haulage company delivered compost containers to the site.

Within two months, the team found that diverting 80% of their waste to organic recycling indeed provided hard savings.

How to Define Process Improvement Success Criteria?

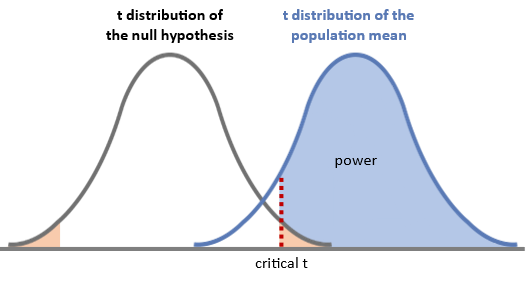

In the Lean Six Sigma world, we measure success by using statistics to prove that an improvement has had an effect. We measure the “before” and “after” states of a process we have changed. We do this using a Hypothesis Test, the most common being the 2 Sample t-Test.

In a 2 Sample t-Test, we compare the average measurements taken before and after making the change. We then take the test statistic (t in the graphic above, the difference of group averages / standard error of difference). We compare the test statistic to the critical t value, which is based on the significance level and degrees of freedom, derived by the size of the two population groups. If the test statistic is above the critical t value, we can reject the null hypothesis and conclude that the change was significant.

In the above example, we compared the grocer’s garbage hauling rates before and after the change. We could easily get the before measurement using the grocer’s many years of periodic garbage expenses. After two periods of measuring the new composting expenses, we were able to successfully reject the null hypothesis and declare that the change was most likely a win.

Process Improvement and the Plan Do Check Act Cycle

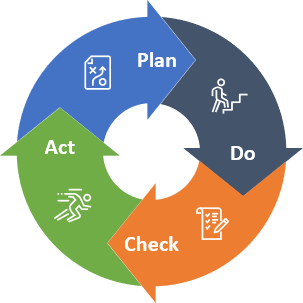

This example shows how you can use the Plan Do Check Act cycle to make improvements. The team planned out how the organic diversion would be accomplished. They then did the proof of concept. As they changed the process, they checked the progress.

As they checked their progress, they discovered a significant amount of garbage was going into the waste stream. In fact, they discovered 10-gallon plastic buckets from the bakery department made up much of that waste.

The team, now infused with a recycling mentality, looked for a way to divert the buckets from the waste stream. They connected with a plastics recycler which was, as it turned out, very near the grocer’s distribution center. They developed a new plan to use the delivery trailers to back haul the buckets to the distribution center. The grocer could then accumulate the buckets and ship them to the plastics recycler.

This change was not as lucrative as the organics diversion, as it needed more labor and coordination. Additionally, the cost savings were not as great as they could only get five cents a pound. And the buckets, although larger, weren’t very heavy. On the plus side, the buckets no longer went to the landfill, so the grocer’s landfill waste cost went down. It was a win-win-win! The grocer received money for the plastic, their waste cost decreased, and the company became more eco-friendly.

What Next?

We’ll go over Step 5 in the final installment, where we’ll get your ideas adopted in the field. And if you have questions or want to discuss testing your process improvement ideas, you can always reach out to Axsium’s productivity team.