Five steps to build a culture of process improvement and continuous change and realize sustainable productivity results.

Axsium’s industrial engineers and workforce management specialists have spent decades identifying and implementing process improvements for our customers.

Regardless of whether process improvement is the primary focus of a project or a value-added opportunity that we uncover along the way, the Axsium team is always on the lookout for improvement opportunities. In fact, we encourage our clients to adopt the same mindset.

We have translated these insights and experiences into five straightforward steps to help your organization get started:

- Step 1: Get to know the proven methods.

- Step 2: Get acquainted with the tools.

- Step 3: Get your ideas prioritized.

- Step 4: Get testing in the field.

- Step 5: Get ready to adopt.

In Parts 1 and 2 of this blog series, we surveyed the available methodologies and recommended tools for generating improvement ideas. In this blog, we will explore tips and tricks for organizing and quantifying your ideas and ultimately prioritizing them.

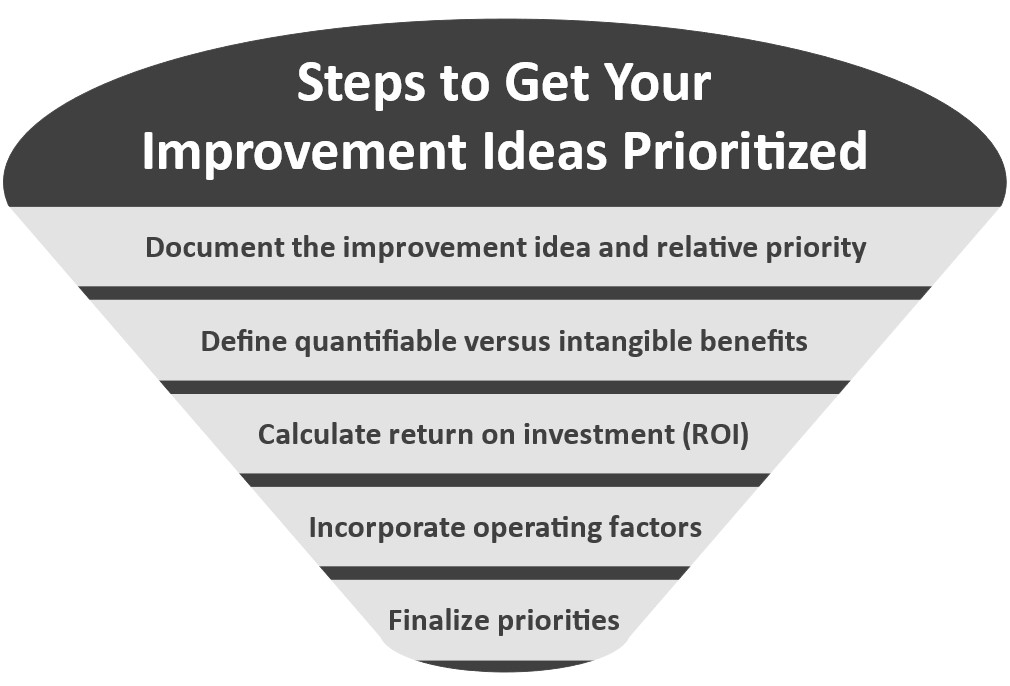

Step 3: Get Your Process Improvement Ideas Prioritized.

Once you start using process improvement tools, you won’t be able to stop the ideas coming. In fact, figuring out where to take it from there will be the difficult part. Not all process improvement ideas are created equal, so we will take you through five straightforward steps to prioritize your backlog. You’ll be able to introduce the most achievable and value-driving ideas to your company as soon as possible.

Document Your Process Improvement Ideas and Relative Priority

You’ve generated a list of process improvement ideas. Great! Now it’s time to begin sifting and sorting them.

First, you need to understand the context of each idea. It’s likely you won’t have come up with all the process improvement ideas you’re prioritizing yourself. Context will help you understand the reasoning behind them and this in turn will help you sell the ideas later.

For example, did the idea come from a specific conversation with a store team member (i.e., brainstorming)? Or did a real-life scenario raise concerns or lead a team to try something different on the spot (i.e., observation)? Or did a set of operational data perhaps help illuminate a path to a potential better way of doing things (i.e., analysis)?

Second, remember to document the change in process each idea will entail. After all, every improvement is based on something that already exists. However, if you’re documenting a process for the first time, be sure to capture the current state in enough detail that you can compare it with the proposed future state.

If they’re available and up to date, Standard Operating Procedures (SOPs) and labor standards are an ideal reference. If the change is approved, you’ll need the SOPs for the roll out. And the labor standards are your benchmark for measuring the improvement.

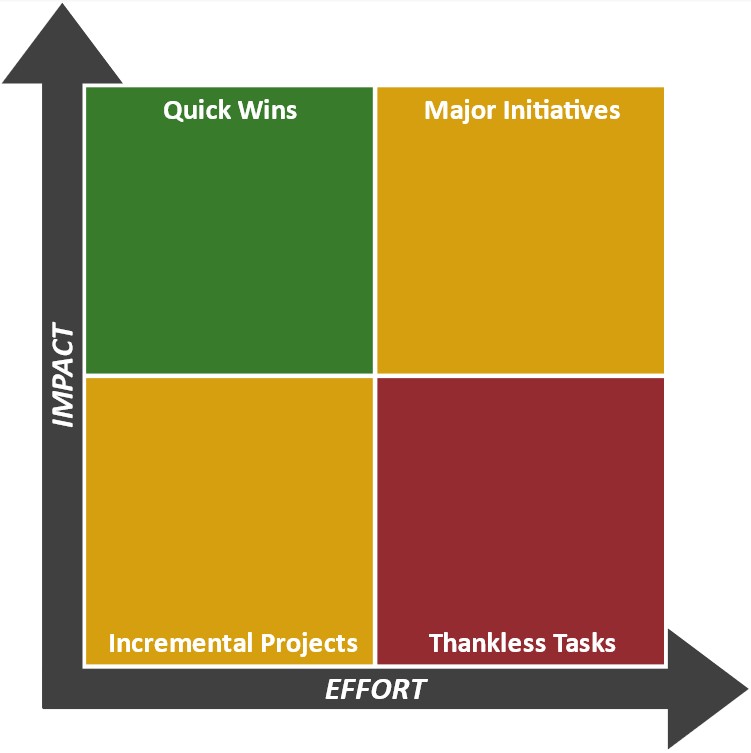

Effort Vs. Impact Charts

You’ve established the context behind your process improvement ideas and documented the current state that you’re intending to improve. Now you can prioritize them based on the information you’ve already gathered. One of the best tools for this is an Effort vs. Impact chart.

To efficiently map your priorities, estimate the relative impact and effort of each one using categories like High/Medium/Low or a simple 1-5 scale. Doing this now will help identify ideas where the juice just isn’t worth the squeeze. We’re sure you can see how this will save you time and effort further down the line.

More importantly, this process will also help you distinguish the quick wins from the incremental projects. Even better, you’ll be able to identify major initiatives, which may tie many related improvement ideas into one program.

Determine Quantifiable Versus Intangible Benefits

Now that you have your high impact and/or low effort opportunities identified, your next step is to consider whether each improvement idea can be measured. If so, you’ll find the benefits will typically fall into two categories: hard or soft cost savings.

You can realize hard cost savingsright away, either by reducing or avoiding existing costs. On the other hand, soft costs savings represent the potential for savings. This can include repurposing time toward more value-added activities or avoiding structural costs down the road.

Will an improvement reduce the resources required (e.g., more efficient food preparation method leads to fewer wasted ingredients)? Then it can be classified as hard savings. Will an improvement lead to reallocating resources (e.g., less work to prepare the food meaning more time to converse with customers)? Then it can be classified as soft savings.

You may not be able to easily measure an idea’s benefits, but that doesn’t lessen its potential impact. After all, many improvements add intangible value, be it enhanced employee morale, brand awareness, or customer loyalty. Remember, even if some ideas don’t seem to offer hard or soft savings, they may be helping your organization achieve larger goals. That can make them worth prioritizing.

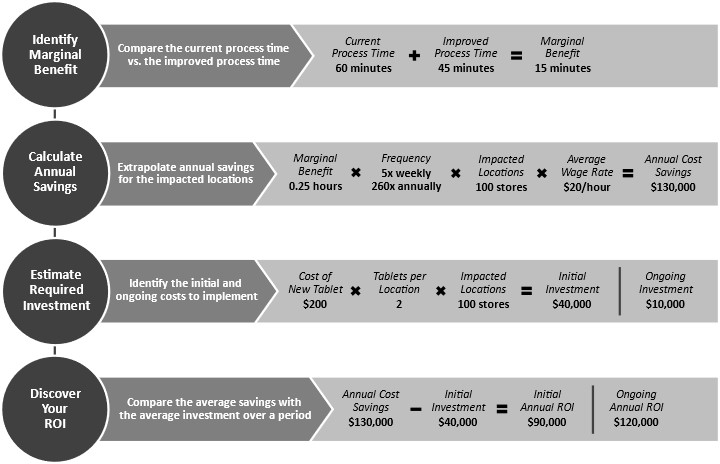

Calculate Return on Investment (ROI)

For those quantifiable process improvement ideas, calculating ROI is the next step. This process always involves making assumptions. You need to instill confidence in your ideas’ business value, so gather as much supporting data as you can.

The most important thing is to measure the incremental change itself. It doesn’t matter whether the change is reduced time or material waste, or increased efficiency or output. The second most important thing is to identify the associated data points formulate the overall financial impact. This can include process frequencies, average wage rates, average number of employees per location, and number of affected locations. Once you’ve done this, calculate the overall cost of the change and find your ROI.

To illustrate how the ROI calculation process typically works, let’s use the example we used in the last blog. Our clients’ inventory process usually took an hour to complete. Our experts tested the process using digital data entry instead of pen and paper and found it took 45 minutes. We identified the improved process would save 15 minutes. The client took inventory five times a week across 100 stores. This led to a yearly time saving of 6,500 hours. Our client was paying its managers $20 an hour, so we calculated the digital entry would save approximately $130,000 a year.

Next, we reviewed how much it would cost to implement and sustain the change. We suggested the client provide tablets to their two managers at a cost of $200 each. Across the 100 stores, we estimated the cost to implement at $40,000 in the first year and approximately quarter the cost in the following years to fix or replace the tablets. Then we could easily discover our ROI of $90,000 in year one and $120,000 each year after.

Incorporate Operating Factors

Now you’ve measured your ROI and identified any intangible benefits, you have a few more things to keep in mind. This includes your implementation timeframe, required leadership support, available funding, and any key risks. Let’s keep using our tablets example to break this down.

When it comes to timing, you don’t only want to know how long it will take to roll out the process improvement. You also need to know how long it will take for the improvement to achieve the desired results. With the tablets, we started with a pilot roll out in a small group of locations. This let us gauge timing as well as the other factors discussed above before rolling out chainwide.

In terms of support, it’s important that you identify business partners and associated initiatives within your organization to help guide the change. For example, the communications team may also be looking for tablets to enable task management capabilities, while the leadership team may already have sustainability initiatives to reduce paper usage.

If your ideas need investment, whether it’s a capitalized expense (as is the case with new tablets) or as part of the operating budget, you will likely need formal approval to move forward. You’ve already built any one-time vs. ongoing costs into your ROI calculation. But it’s also important that you know who owns the budget, how you get it, and how quickly you can allocate it to your cause.

Finalize Your Process Improvement Priorities

To create your final prioritization list, we recommend revisiting your initial Effort vs. Impact matrix. But this time, try using your data-driven ROI analysis and knowledge of the operating factors to fine-tune the y-axis (Impact). And your better understanding of the risks involved can help paint a fuller picture of the x-axis (Effort).

The immediate next steps for your newly prioritized improvement ideas depend on what quadrants they fall into. But you aren’t at the finish line just yet. We’ll go over steps 4 and 5 in the coming weeks. You’ll learn how to get your prioritized ideas properly tested and adopted in the field. And if you have questions or need more help quantifying and prioritizing your process improvement ideas, you can always reach out to Axsium’s productivity team.